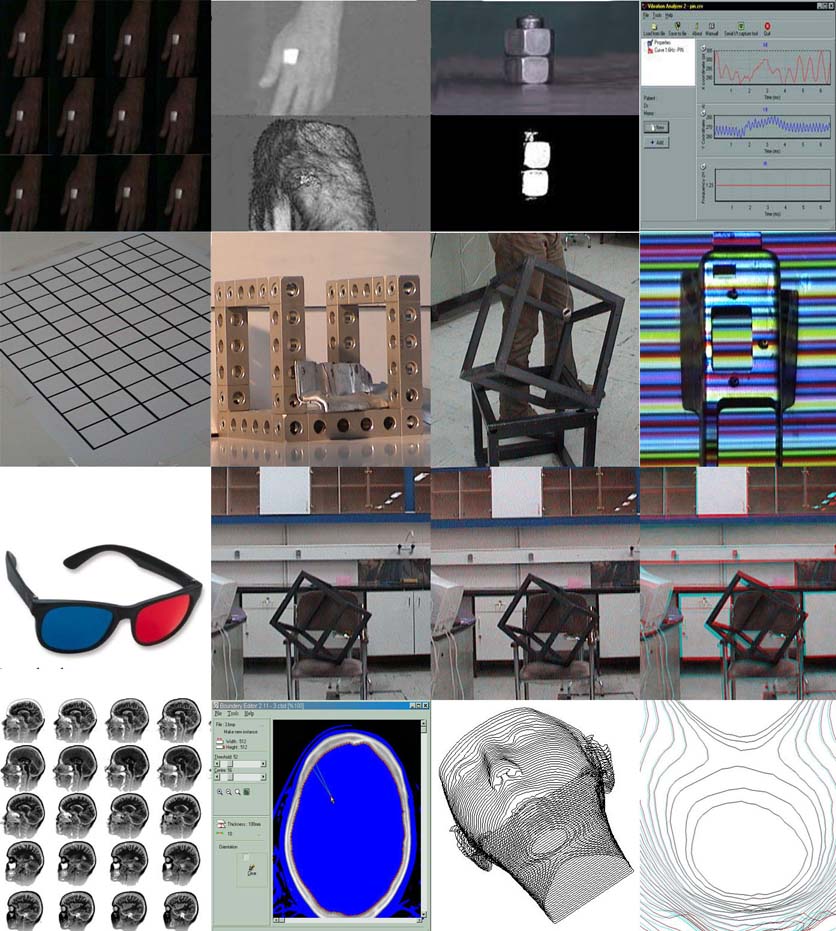

Patients with bone tumors, congenital defects, and abnormal deformities caused by complex fractures, can not be treated using standard knee joint prostheses. These patients usually need specially designed custom-made prostheses to fulfill their requirements. This article describes the development of a computer-aided-design system for design of knee custom-made prostheses. Parallel slices of the patientís distal femur and proximal tibia are obtained using Computed Tomography with variable distances. A software was developed to trace the boundaries of the bones in the CT slices using image processing techniques. The 3-D coordination of the boundaries are saved in DXF format and can be imported to any solid modeling software, e.g., SolidWorks. This leads to a 3-D solid model of the knee joint which can be used for design of the surgical procedure, dimensioning of the prosthesis and obtaining the optimal fixation conditions. A parametric full constrained knee joint prosthesis was designed and constructed as a 3-D solid in SolidWorks. The design provided Flexion/Extension and Medial/Lateral rotations, and Abduction/Adduction laxity. The application of the prosthesis to the knee can be simulated and analyzed in Working Model software. This yields to an evaluation of the functional parameters, e.g., the ranges of motion, the fixation condition, e.g., the shear stresses and micro-motion in the bone-implant interface, and structural strength of the prosthesis for a special patient, e.g., the stress-strain relationships in the metal and polymer components.